When it comes to the selection of custom boxes, one thing that comes to mind is the selection of the perfect dimensions so that the professional look for which we were looking for can be achieved. Whether you are selling products or moving items, understanding how to measure and write will save you a lot of time and money.

So, to make things easy for our readers, we are going to discuss some of the best ways of measuring a box and will give you some practical tips to avoid errors.

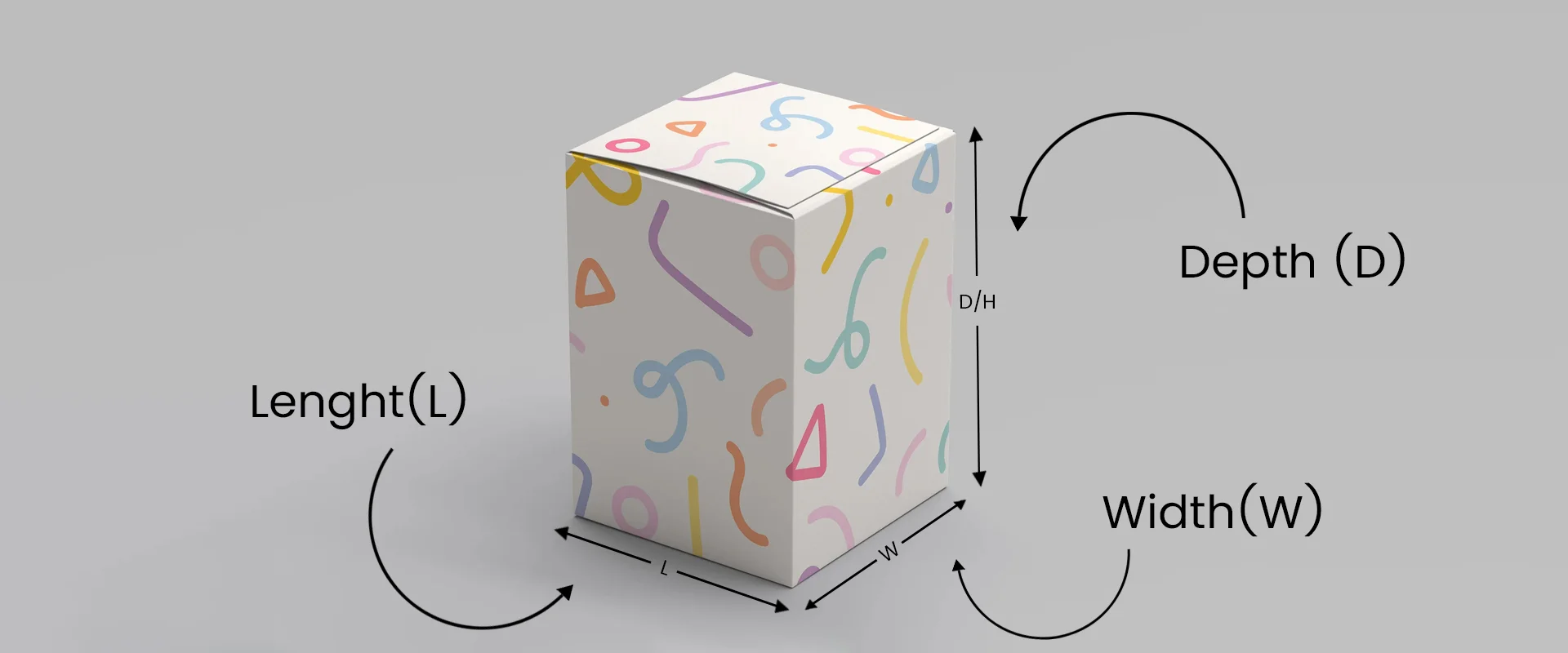

Understanding Box Dimensions

Before understanding the best ways to measure the dimensions of the boxes, let’s first understand the three main components of dimension, namely length, width, and height. These measurements define the size of the boxes and are crucial for the shipping, storage, and designing of the boxes.

Length

Length is the longest side of the boxes. When you are measuring the length of the boxes, the length is the side that runs parallel to the opening of the longest edge of the boxes when it is placed in an upright condition.

Width

Width is the shortest side of the box when you look at the front. This side is perpendicular to the length and represents the distance from one side of the box to the other side.

Height

Height is the measure that denotes how tall the box is. It is essential to stack and fit the boxes into storage places and to make sure that the product is placed perfectly.

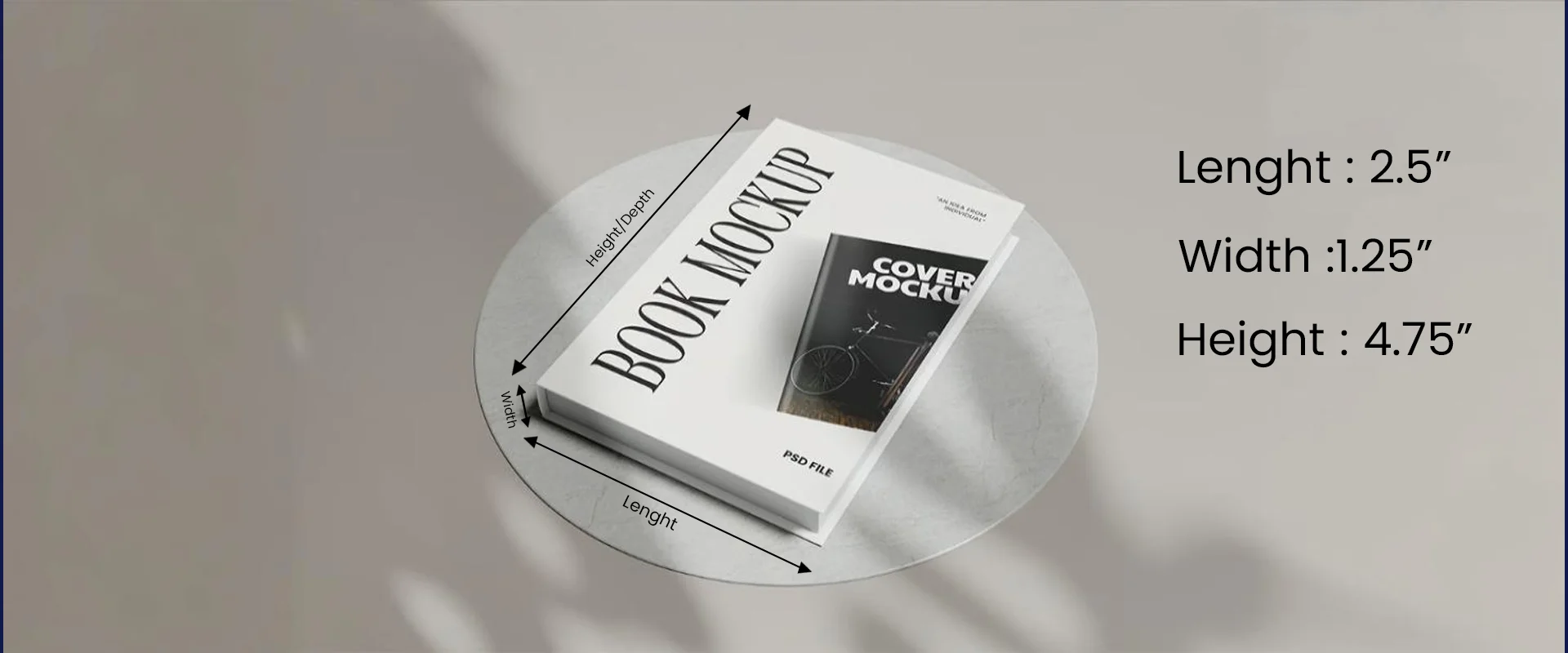

How To Measure A Rectangular Product?

Let’s take an example to measure the dimensions of the rectangle product. As shown in the image, the height of the box is 4.75 inches, and it is 1.25 inches wide with a length of 2.5 inches. Then, the dimensions of the product will be written as follows:

Dimensions: 2.5″L x 1.25″W x 4.75″H

When writing dimensions, one thing you must keep in mind is consistency. While writing dimensions, choose one format and stick to it. Some of the common formats understandable by the maximum industries are as follows:

- Standard Format: L x W x H

- Alternative Format: Length x Width x Height

- Abbreviated Format: L x W x H or L/W/H

For example, the dimensions of a box can be expressed as:

2.5″ x 1.25″ x 4.75″

2.5″L x 1.25″W x 4.75″H

How To Measure A Cylindrical Product?

In case you are selecting a cylindrical material then the measurements may vary slightly. A cylindrical box is defined by its height and diameter. Multiplying them you can get the dimension of your cylindrical box.

Is It LxW or WxL?

One of the common questions encountered when measuring box dimensions is whether to write dimensions as LxW or WxL. The answer is simple, you must always write LxW. It does not impact the mathematical calculation, but it is a convention to write length first, then width, and then height. This helps maintain clarity and consistency across all the measurements.

How To Measure A Box

Measuring the box with accuracy is a crucial task so that you can pack a specific product perfectly or place the box in your selected space without any hassle, specifically at the time of shipping. Let’s see the best and the easiest ways to measure a box.

Tools You’ll Need

- Measuring Tape: Make sure you select a flexible tape so that the dimensions of your custom box can be measured accurately.

- Ruler or Yardstick: If you have to measure a small box, then a ruler or yardstick is also appropriate.

- Notebook and Pen: To jot down measurements.

Step-by-Step Guide

Place the box on a flat surface and ensure that it is stable. This is essential for accurate measurements.

Measure the Length

- Now position the measuring tape along the longest side of the box.

- Now, jot down the measurements in inches or centimetres.

Measure the Width

- For width, measure the box across the shortest side.

- Retake the measurement to ensure accuracy.

Measure the Height:

- Measure the base to the top of the box

- Retake measures for accuracy.

Double-Check Your Measurements: It’s always a good idea to measure twice to ensure accuracy.

Example Of Measuring a Product

Let’s say you have a box with a length of 4.75 inches, a width of 1.25 inches, and a height of 2.5 inches. The measurements will be recorded as:

Length: 2.5 inches

Width: 2.5 inches

Height: 4.75 inches

This box can be represented as 2.5″ L x 2.5″ W x 4.75″ H.

Box Dimensions For Custom Boxes

The measurement process for custom boxes is a little complex because you have to design them for particular purposes and products. Some tips for writing dimensions for custom boxes are as follows:

Understand The Product Size

Begin designing custom boxes only after measuring your packaging requirements. The dimensions of custom boxes need to be precise to achieve a tight fit so that the product does not juggle inside the box.

Consider Additional Space

When packing delicate objects, always allocate ample room for padding materials, such as snowflake cushioning or packing peanuts.

Design For Ease Of Use

The box opening and closing functions need to be considered. This is necessary so that if you are selecting the boxes with tuck ends, the lids can be tucked in without any difficulty.

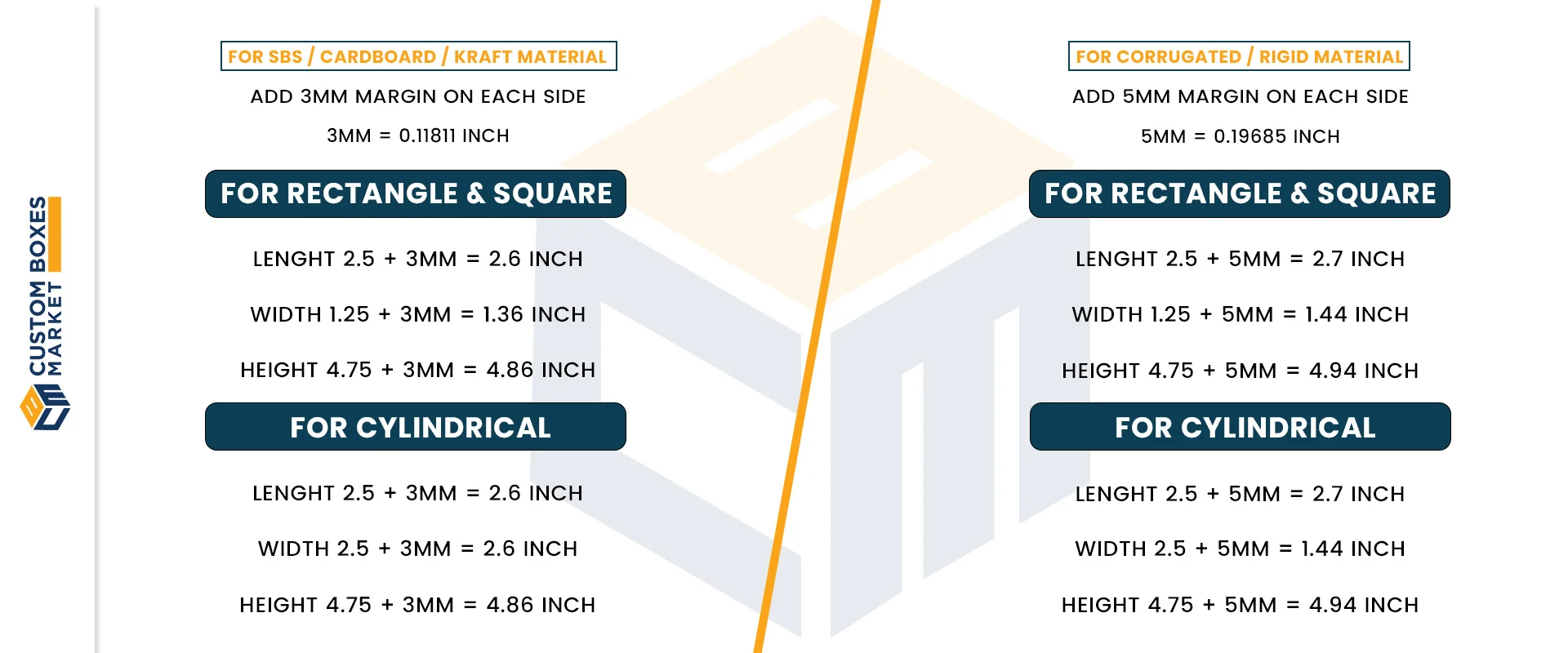

Consider The Material

When it comes to the measurement of custom packaging boxes, then one thing that you must consider is the type of material you are using. This is because different materials have different thicknesses that impact the inner core of the boxes. For each material you have to add the below-mentioned inches or mm on each side of the box:

- Cardboard: 3mm

- Kraft: 3mm

- Corrugation: 5mm

- Rigid: 5mm

Final Thoughts

Anyone who ships product packaging runs a logistics company or simply has a product-based company where packaging is required must understand how to measure a box. Choosing the dimensions LxWxH and taking precise measurements will ensure that your boxes are of the perfect size for the product required to be packed.

The precision of your measurements, combined with standard or custom box dimensions, guarantees that your packaging is free from potential problems, such as damaged goods or wasted space.