Have you ever seen or run your hands through a topographical globe, which has the world’s peaks and valleys projected outwards? You cannot help but touch it because it appeals to the eyes. Embossing has similar effects.

Embossing and debossing are two printing techniques which are used to impress or depress text or images onto paper. It can be customized according to the customer’s needs on the packaging boxes to enhance the visual appeal of the box and give it a premium and luxury packaging look. We will further discuss the different types, benefits and uses and mainly the differences among them.

What Is Embossing?

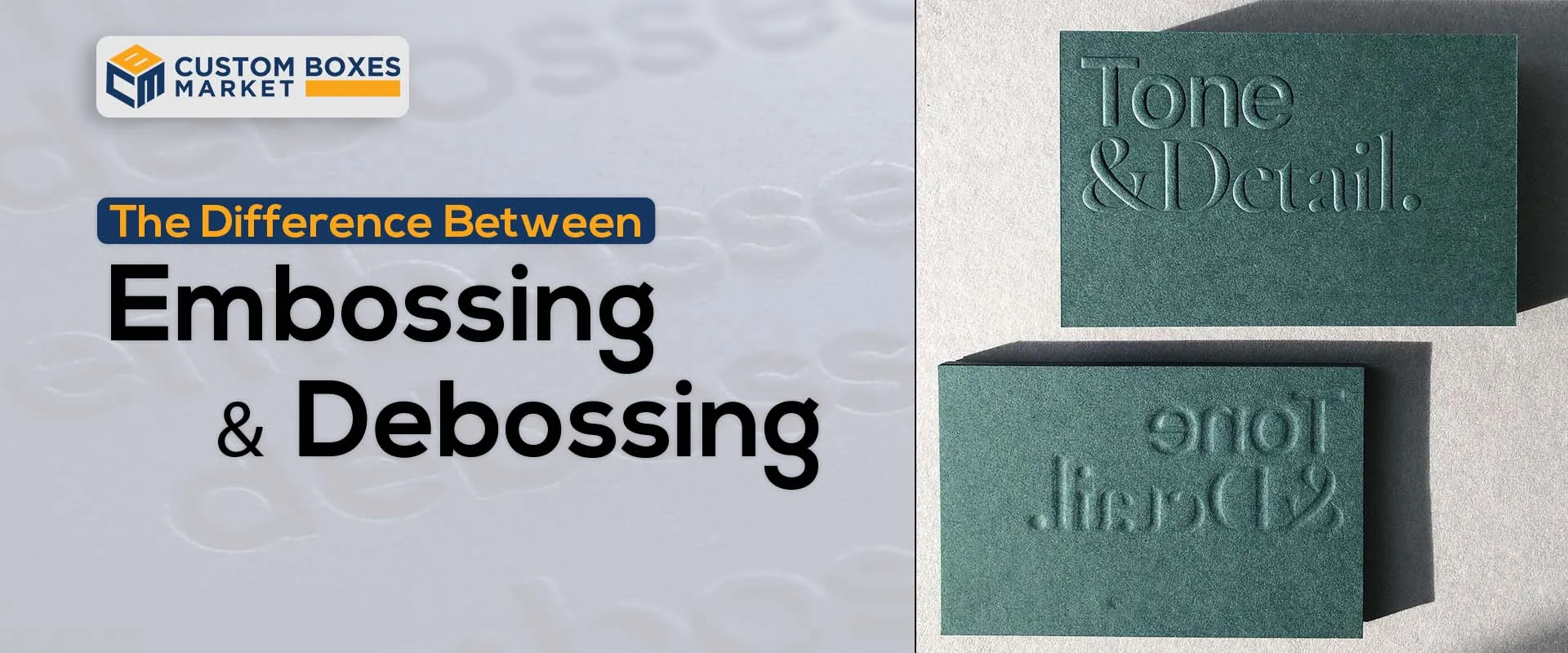

Embossing is a process in which a design or text is stamped on the material that gives the text a raised look. Two main things are used for embossing, a die which is a personalized metal plate and stock, which is paper.

What Is Debossing?

Debossing is the opposite of embossing. In this process, design or text is indented on the material. You can also add ink and foil stamping to it.

Difference Between Embossing And Debossing

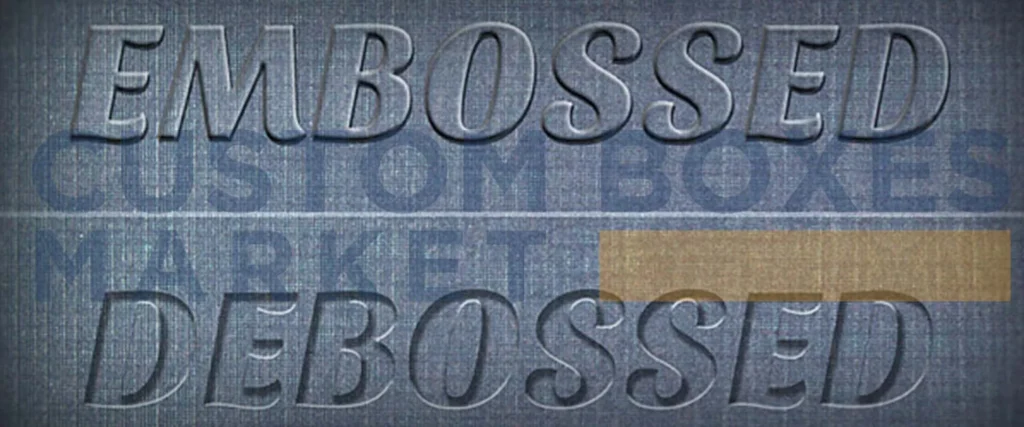

The main difference between the two processes is the effects they create. Embossing involves producing a three-dimensional image or design raised upwards. Many companies often use embossed logos, custom illustrations, initials, or a pattern for a luxurious effect. Embossing can be done on a diverse range of materials like metal, acrylic, leather, wood, cloth, and paper.

On the other hand, as the word says debossing is the opposite of embossing. It uses a combination of heat and pressure in a design or text creating a depressed effect. It gives a subtle and elegant touch, giving the design or text a subdued and sophisticated look.

Process Of Embossing

The process of embossing involves two metal plates, known as dies, that cut with the desired image. A metal plate is then pressed into the paper from underneath using heat and pressure, raising the image into the corresponding die. The final resulting shape can then be inked or foiled for an additional effect.

Benefits Of Embossing

Embossing has benefits that will give your packaging a new look. It will help your brand stand out in the market from the other products.

- It gives a 3D effect that stands out and is visually appealing.

- It is much easier to apply foil stamping on the raised material

- It can pass good details to the die pattern.

- It increases the product value.

Types Of Embossing

Embossing has diverse types customers can customize the retail packaging boxes however they like. The names of different types of embossing are mentioned below.

- Single level embossing

- Multi-level embossing

- Blind embossing

- Registered embossing

- Combination embossing

- Pastelling embossing

- Glazing embossing

- Scorching embossing

Read More: 10 Ways Digital Printing for Packaging Can Transform Your Business

Process Of Debossing

Two dies (metal plates) are made with designs. A heated press is used to insert the die. Cardstock, paper, or other materials are sandwiched in the press. In the final step, dies are pressed with force on the surface of the material, leaving the indented pattern.

Benefits Of Debossing

Debossing has benefits that will create a packaging look which outshines the other. It will help your brand stand out in the market from the other products.

- It creates a depth in the box with the dimensions you want to add.

- Your design’s back will not be affected by this negatively.

- These effects give your products a more unique and high-end look.

- Using ink in such custom boxes will be much easier.

- This effect allows your packaging to be more attractive.

Types Of Debossing

Debossing has various types customers can customize the packaging boxes according to their budget and their preferences for packaging designs. Different types of debossing have been discussed below.

- Blind Debossing

- Registered Debossing

- Combination of Embossing and Debossing

- Foil Stamping With Debossing

- Multi-Level or Sculptured Debossing

Blind Debossing

Blind debossing is a type of debossing technique. It is done by pressing the design into the material without the use of ink or foil. It can make deeper imprints which help create a subtle, yet elegant effect.

Registered Debossing

Registered debossing is a type of debossing that blends printing with debossing. The design and pattern are printed with ink onto the material to give it a nice finishing look.

Combination of Embossing and debossing

Combination of both embossing and debossing to create designs with contrasting textures. Different materials paper, cardboard, fabric, and some plastics to create elegant stationery, high-end packaging, fashion design, and more.

Foil Stamping With Debossing

In this process of debossing, the foil is applied to the material before debossing. It is often used with paper, cardboard, and leather for luxury packaging and stationery, premium leather goods, and promotional materials.

Multi-Level or Sculptured Debossing

This is a process in which multiple depths are created within the design to add dimension and complexity. Sculptured debossing can be used with paper, fabric, cardboard, and leather to create textures and adornments in parts.

Read More: What is Spot UV Printing? Its Uses, Benefits, And Types

Conclusion

The reason behind embossing and debossing is aesthetic. For instance, embossing works well in printing greeting cards, letterheads, paper products, as well as other packaging materials. If you want either embossing or debossing for your custom packaging boxes, Get in touch with us at CustomBoxesMarket.ca if you want to give your product a magical transformation.